Vision system, Ultrasonic Welders, Screw gun software, and solutions

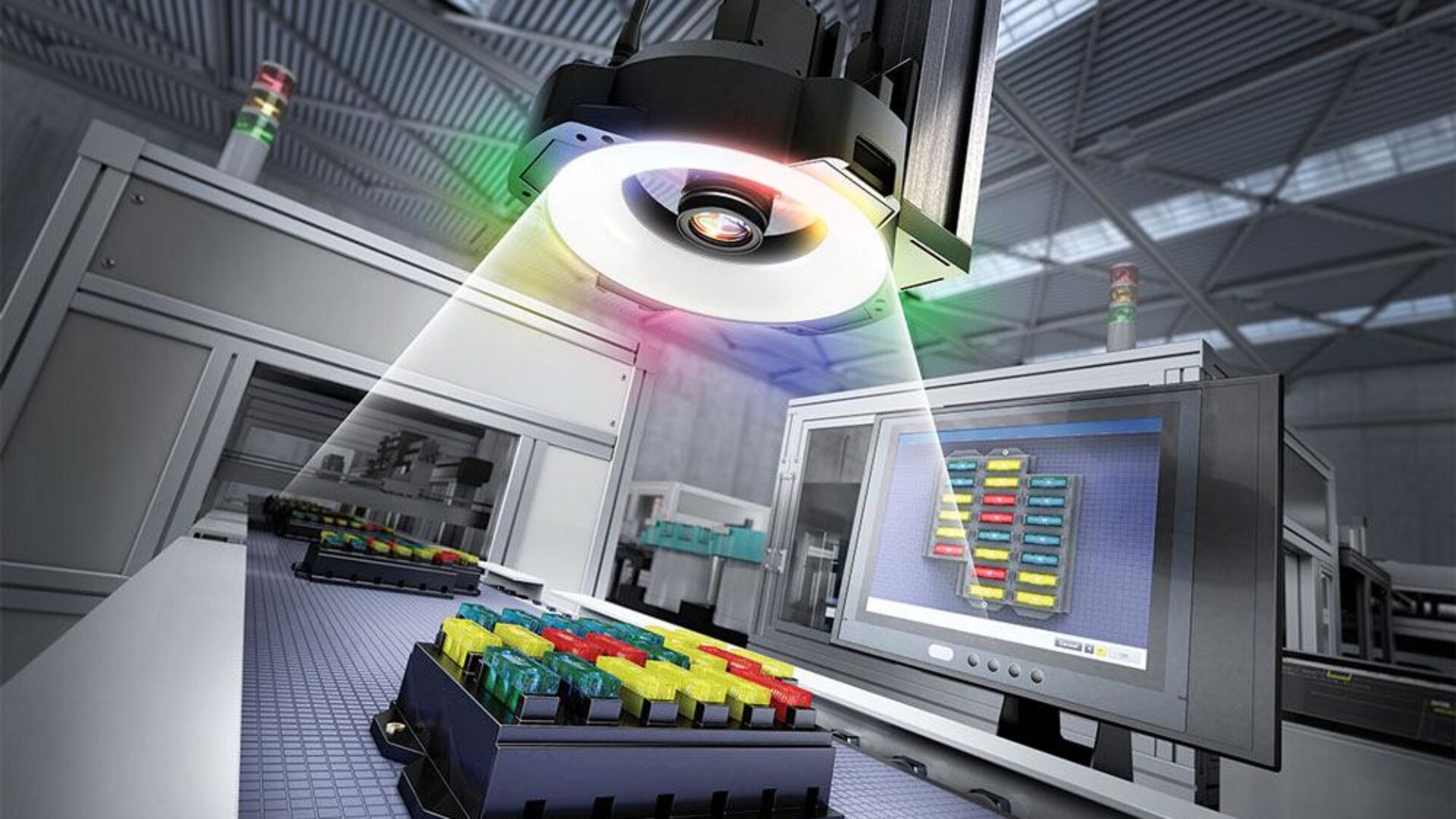

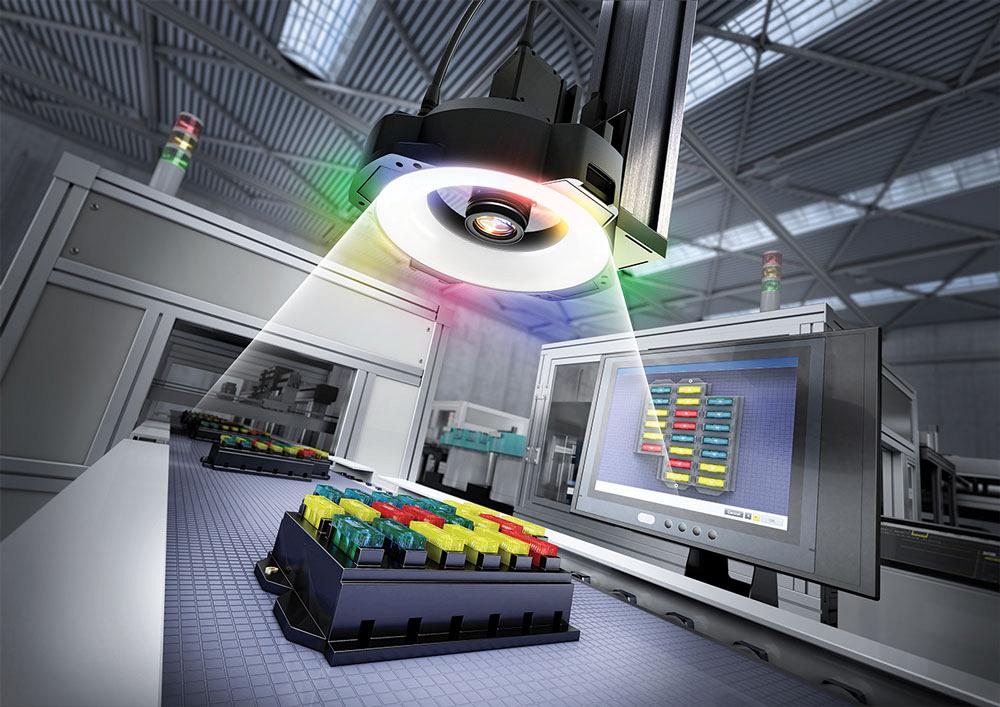

Flexible Smart Camera Configurations

Our smart Turnkey cameras are produced to deliver fast processing times and support for high resolution options. A unique means that can be executed without any moving parts, making adjustments easy to accomplish. The Inspection Manager software makes changing between product inspections profiles simple, and can export production data easily. Cameras and profile lasers for 3D inspection, and area cameras up to 21 megapixel for the highest resolution requirements can be connected to any industry. Flexible programming high-quality, high-speed inspection and control to solve various types of industries’ demands.

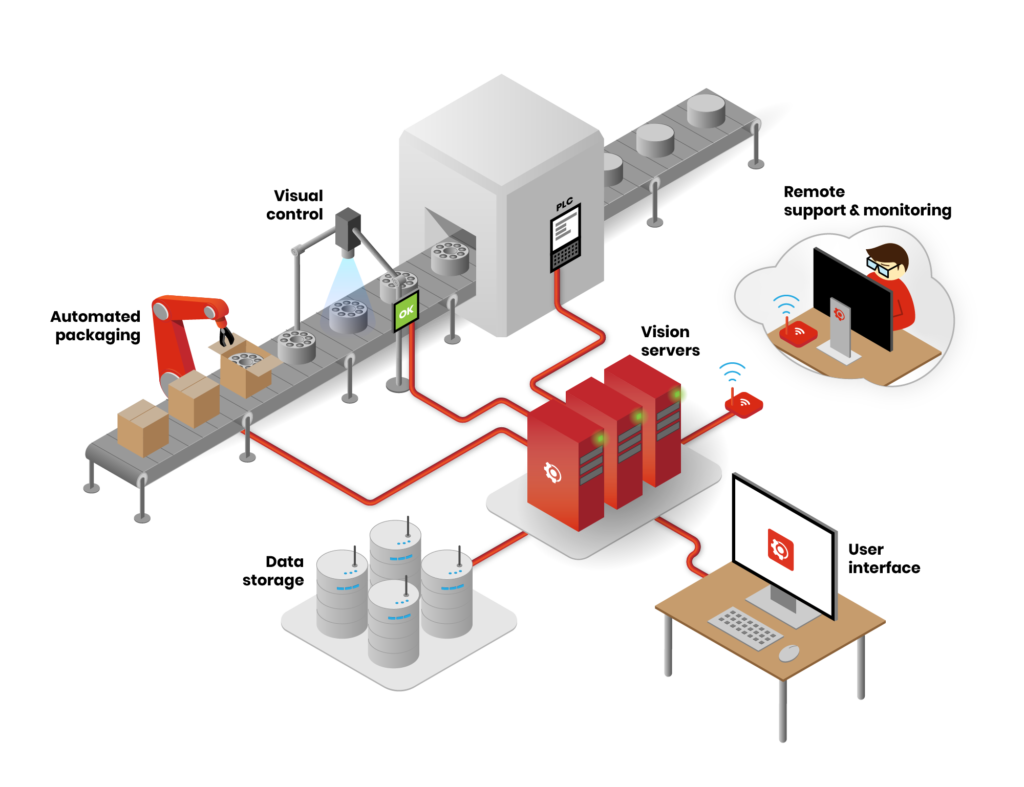

VISION SYSTEM DATABASE

Inspection of products with machine vision in a manufacturing environment is a critical part of insuring quality and customer satisfaction. Inspection results need to be analyzed to resolve the cause of an unexpected production problem or to investigate a customer concerns, integrating an effective system of thorough inspection data with the corresponding machine vision images has traditionally been very difficult and expensive.

Vision database makes it easy to collect, search, analyze, and verify. Compare result data with the actual machine vision image captured at the time of inspection made easy. Great amount of data sets can be managed safely, automatically traces changes in inspections settings and output items during operation.

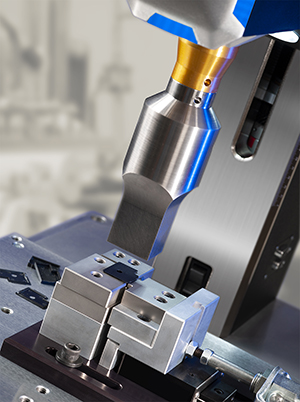

Ultrasonic welding

High-frequency vibration to melt and weld plastic. A tool vibrates at ultrasonic frequencies and causes concentrated molecular vibration in the weld joint. The friction between the molecules heats and melts the plastic. Once the vibration is stopped, the tool maintains a holding pressure on the joint to create a bond. Turnkey ultrasonic machines for automotive applications, medical technology and food industry.

Barcode Readers

Turnkey full traceability, solutions and leading readability. Wider field of view compared to conventional models it will allow for easy reading of multiple codes and varying code positions. Reading distance will exceed that of conventional models. Work-ability, relatability and

Automatic setting of exposure time

The code reader automatically optimizes the exposure time, image processing filter and other parameters according to the target and mounting distance.

With just the push of a button, automatic focus, tuning and polarization are utilized to achieve a seamless read every time

An extensive range of handheld and fixed mount 1-D / 2-D barcode readers for industrial applications.

productivity. Reading codes, from moving conveyor belt made easy for. A breaking solution for logistics or production.

Torque screwdriver

Innovative, ergonomic and durable electric torque fastening systems. Our applications will ensure repeatable torque no matter what your assembly application needs.

In our application technology Facility, a team of highly trained engineers conducts detailed feasibility studies and test series to find the optimal solution for your applications.